What you need to know when you are ready to get a lift solution.

Lift platform, a kind of lifting tool, have spread throughout all aspects of our production and life, and are widely used by people in construction and daily life. When you have a working environment that requires this kind of lifting equipment and are planning to purchase it, you may be concerned with these issues.

To avoid unnecessary problems down the road, choosing a trustworthy supplier is an important decision.A professional supplier can provide you with the most suitable lift solution to improve work efficiency.We give some suggestions as follows:

- Relevant certificates and production standards of the lift platform factory.

- Experienced designer team

- High-precision production equipment

- Efficient after-sales team

- Any sales experience in the local market.

WIZ LIFT is an ISO certified lift platforms manufacturer in North of China,and all products compliance to CE certificate,and also can customize different standards qualified lifts for different countries.

For standard products, such as aerial work lifting platforms, mobile loading dock ramps, and some fixed dock levellers, they can be suitable for the working environment. However, for some customized lifts, the supplier needs to issue relevant design plans and drawings based on the required lift load, height, and platform.

- Provide Shaft Size/Site Picture or Loading capacity/Platform Size/Travel Heigh

- Design and confirm the customized lift drawing

- Signing the contract

- Payment by TT or LC

- Lift table manufacturing

- Delivery according to delivery date requirements

- Lift Equipment testing in factory

- Packing and shipment by LCL or FCL

- Installation Instrucstions provided or video guidance as required.

- Lift usage and subsequent maintenance training

Delivery Time:

Standard Lift Products:Delivery time:10days

Customized lift Products:

- Delivery Time:within 30days.( Except for special lift platform designs)

Shipment:

- LCL: wooden box with iron frame

- FCL: most lifts will be designed based on 20″container.Some special heavy duty lifts maybe shipped by 40″container.Based on different projects

If you don’t have a logistics agent or customs clearance agent, we can help.Supporting Door to Door Service.(DDP terms is acceptable).Then you can get your lift very easily after ordering.

We have professional testing team who will do standard testing before shipment.May have different test ways based on various lift platforms.

- For standard lifts(like aerial working platforms ),standard testing procedure.

- Scissor lifts.All specification details will be inspected,including Paint appearance, platform size,loading capacity,travel height,lift self height,details parts,safety marks,spare parts etc.

- For guide rail type goods lift and four post lift tables,extra pre-installation can be provided in lift factory.

WIZ LIFT team ensure qualified lifts for your projects.

After downgrading to the destination, you will need some common loading and unloading tools, such as a crane or forklift. For the convenience of loading and unloading, we have arranged lifting ropes or lifting hooks when loading the lift platforms in our factory.

Our prices are different for different lift platforms. For example, standard lifts can be produced in batches, so the profit margin will be relatively small and the cost will be low.

For some customized hydraulic lift platforms, because the costs will be higher, the price will also change according to different design plans. For example, the price of a car lift or cargo lift /Mezzanine freight elevator vary depending on the lift travel height, load capacity and lift table size.

A small cargo lift may only cost 1,500 USD, while a cargo lift with a large load capacity and high height may cost as much as 15,000 USD. Therefore, if you currently have a project that requires the installation of a lift platform, please feel free to contact us and we will provide a lift design plan and quote within 24 hours.

When you choose to buy a lift, installation may be an important issue for you to consider. As a supplier with many years of export experience, we have taken this issue into consideration for you. If you purchase our lift, you will enjoy the following services:

- Total FREE installation instructions

- 7*24hours Video installation guidance

- Site installation guidance with only travel and accommodation expenses

Judging from the 26,000 projects we have served, 99% of lift buyers can install it themselves.

If you are in the lift or elevator industry, or are contracting projects, have a certain customer base, and have corresponding installation teams or after-sales capabilities, we welcome you to consult us about agency matters. Now, we have agencies in five countries. We look forward to your joining!

We have a longer warranty period(5 YEARS) and better quality warranty services than other suppliers.Choose our hydraulic lift platforms,enjoy excellent quality!

When you choose to purchase a lifting platform, or you may encounter some problems during use, as a professional lifting platform supplier, we are very happy to provide some professional knowledge on the maintenance and repair of lifting platforms.

Other lift related questions you maybe interested in?

With the rapid development of aerial work platforms, they are widely used in all walks of life, and how to choose aerial work platforms has become a big problem. In fact, there are certain skills when purchasing aerial work platforms. Three points are listed below for your reference.

- First of all, you should judge which aerial work platform you should buy according to the construction environment. For example, if you are working in a small space or on an indoor flat ground, if you need efficiency and the ground is relatively flat, you can choose the mini scissor type.WIZ LIFT produce a mini electric scissor lift,this self propelled scissor lift dimensions1280*760*1880mm.It is very suitale for working in a wroking in places with limited space.

In short, there are no less than 10 styles of aerial work platforms on the market, and the one that suits you is the best.

- When purchasing an aerial work platform, you cannot buy it blindly. It is necessary to do sufficient market research and on-the-spot inspection to determine the size of the company and its degree of credibility. This is first and foremost. Now many small-scale enterprises in the market cut corners in order to seek violence, which greatly reduces the quality of lifting products. Although they will sell very cheaply, this kind of machinery does not take long and has a high risk factor. Therefore, as a purchaser, you can’t covet a little bit of cheapness and lead to greater regrets.

- Based on the information you have investigated, choose a high-quality aerial work platform based on its technical parameters, practicability and versatility.

4.The technical parameters and uses of each are slightly different, but there are also many similar functions. Therefore, as a customer, you should choose with a purpose.Aerial Work Platform Boom lift Aluminum lift scissor-type aerial work platforms 22m or higher 4m to 22m Mobile scissor lift Electric scissor lift 4m-18m 4m to 14m

There are two main types of hydraulic lifts, scissor lifts and rail lifts.

Hydraulic cargo lifts have been widely used by the public and are very mature vertical lifting equipment with good safety performance, but many friends know too little about this product. Today, I will introduce the safety performance of hydraulic cargo lifts.

The safety guarantee of the hydraulic lift freight elevator is divided into two parts:

Part I: The safety guarantee of the hydraulic power system.

The hydraulic power system is a power system with very good safety performance and stable performance. The hydraulic system has multiple safety protections. In addition to the chain drive, the mechanical part also has a steel wire rope to play a safety role.

Part II: Safety Guarantee for Mechanical Parts

First of all, as far as the structure is concerned.

The structure of each equipment directly determines its safety, and the fall of the elevator and the luxury elevator also occurs. It is a straight-line hydraulic cylinder. As far as the lifting structure is concerned, the hydraulic system is safer. Now many elevator manufacturers have improved their elevators with reference to our hydraulic lifting freight elevators and started to produce hydraulic elevators. The price is safer than conventional elevators. It can be seen that our hydraulic lift freight elevators have a strong safety guarantee in structure.

Secondly, there are a lot of safety protection facilities.

Although our hydraulic lifts are simple and simple, we have a full set of safety devices.

1.Relief valve: It can prevent the system pressure from being too high during upward movement.

2.Emergency manual valve: When the hydraulic elevator fails, the platform can be lowered to the nearest floor to open the door in an emergency.

3.Hand pump: When the system fails, the manual pump can be operated to pump out high-pressure oil to make the car rise to the nearest floor.

4.Pipeline rupture valve: When the hydraulic system pipeline ruptures and the car stalls and descends, it can automatically cut off the oil circuit to stop descending.

5.Oil temperature protection of oil tank: When the oil temperature in the oil tank exceeds the standard set value, the oil temperature protection device will generate a signal to suspend the use of the elevator. When the oil temperature drops, the elevator can be started.

Finally, the hydraulic lift freight elevator needs the messenger to operate correctly and strictly abide by the safety operation rules of the guide rail type lift freight elevator.

If you want to establish a cargo lift,just must know the following information:

| Lifting height | Platform Size/Shaft Size | Loading capacity |

| 8000mm | 2000mm*1400mm | 2000kg |

| (for example) | (for example) | (for example) |

No matter how safe our hydraulic freight elevator is, if the user does not operate it correctly, there will be potential safety hazards, so normal operation is the guarantee for the safety of the hydraulic elevator.

The hydraulic lift freight elevator is a kind of lifting equipment with good safety performance. As long as the buyer chooses a regular cargo lift manufacturer and strictly follows the operating regulations in use, the safety can be guaranteed.

The car lift platform is a special hydraulic lift platform for vertically transporting cars. It is mainly used in the transportation of cars up and down between various working floors such as building parking lots. It is especially suitable for low-rise buildings. It is a safe and ideal car transportation equipment.

Applications:

It is suitable for lifting large loads, with high safety performance, stable lifting, and simple and convenient operation. Simple and suitable for various architectural designs, it can save the building space without the need of the top-floor computer room.

Classification of household car lifts:

Home car lifts can be divided into three common types: scissor-type car lifts, rail-type car lifts, and four-post car lifts.

Figure 1: Scissor Car Lift

The home scissor lift is generally suitable for installation in the underground garage to the second floor to facilitate the parking of family cars.

Features:

The scissor lift platform is a special hydraulic lifting platform used for transporting goods between floors of buildings. The products are mainly used to transport goods up and down between various working floors; three-dimensional garages and underground garages are used to lift cars between floors. The hydraulic system of the product is equipped with anti-fall and overload safety protection devices, and operation buttons can be set on each floor and the working surface of the lifting platform to realize multi-point control. The product has a solid structure, large carrying capacity, stable lifting, simple and convenient installation and maintenance, and is an economical and practical ideal cargo conveying equipment to replace elevators between low floors. According to the installation environment and use requirements of the lifting platform, different optional configurations can be selected to achieve better use results.

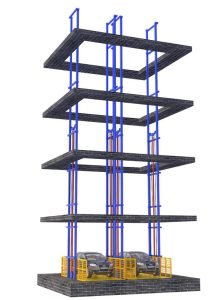

Figure 2: Guide rail car lift.

Rail-type lift platform (Rail-type lift platform) is a hydraulic lifting platform, which consists of a hydraulic lifting part, a guide rail and a loading platform.The rail chain type lifting platform has a wide range of applications, and is mostly used for the transportation of goods between floors in industrial plants, restaurants and restaurants, and the up and down handling of goods in chemical factory warehouses.

–Applicable places

- Cargo transmission between floors of two- and three-story industrial plants, restaurants and restaurants

- Industrial occasions where pits cannot be excavated

- Material transportation between floors at high-rise construction sites

–Features:

◆Sturdy structure, rail-type car lift platform price, large carrying capacity, stable lifting, easy maintenance.

◆It has strong installation adaptability and can be installed in harsh environments and explosion-proof places;

◆Widely used, the material of rail-type car lift platform is suitable for the transportation of goods between floors in most industries;

◆Flexible configuration, rail-type car lifting platform, according to different positions and use requirements, flexible configuration of platform size and import and export direction;

◆Economic and practical, less investment and lower maintenance costs, no need to build a special machine room, saving construction budget;

◆Safe and reliable, the guide rail car lift platform is 6 meters, and the safety valve for overload protection and pipeline burst fully guarantees the safety of operation;

–Scope of application: Widely used in basements, warehouse renovations, new shelves, chemical plants, production workshops and other places, suitable for the transfer of goods between the floors of industrial plants, restaurants and restaurants on the second and third floors, industrial and mining enterprises instead of elevators to lift goods, especially suitable for belt conveyors Wells and places where foundations cannot be dug underground.

The rail-type car lift has a higher lifting height than the scissor-type car lift, and is driven by a heavy-duty chain and wire rope to ensure the safe operation of the machine. The equipment runs smoothly, the product structure is firm, the bearing capacity is large, the installation and maintenance are simple and convenient, and it is more suitable for the working environment where the foundation pit cannot be excavated. The car lift can only be used for evenly loaded car transportation occasions, and cannot be used as an ordinary platform or conveying personnel. Automotive hydraulic lifts come with a complete operating device, button box and safety guardrail.

Figure 3: Four-post car lift

Four-column lifting platform parameter description

- Parameters introduction:

- System control: electro-hydraulic

- Power supply: 380v (customizable)

- Load weight: 3.0 tons (customizable tonnage)

- Countertop: 3000*6000mm (2400mm for import and export), the countertop can be customized

- Lifting height: 2000-16000 (mm)

- Power: 5.5 kw

- Lifting speed: 4-6m/min

- Material quality: Q235

- Color: regular blue (optional)

Product performance:

- The structure is sturdy and durable, the bearing load is large, the action is stable, and the noise is low.

- The system performance is stable and reliable.

- In the event of power failure or failure, the lifting platform can be dropped back to the lowest floor by manual operation.

- Using low pressure hydraulic drive technology, the whole system has high safety, reliability and stability.

three.

Car lift advantages

- Automatic leveling, the elevator control platform will automatically stop when it reaches the target floor

Door-machine linkage: the platform reaches the target floor, and the floor door opens automatically (optional)

- High-strength double chain drive, no extension of load, long service life and large safety factor

- High-precision hydraulic transmission, stable lifting, simple operation, low failure rate

- Large displacement pumping station, fast lifting speed and low running sound

- Adjustable screw. The platform is level, and the car is raised and lowered smoothly

- Infrared photoelectric sensor

- Pneumatic safety lock (optional)

- The platform is equipped with overload alarm and partial load protection device to ensure the safe lifting of the platform.

- The car lift hydraulic system is equipped with an explosion-proof valve to prevent the platform from falling due to the rupture of the oil pipe.

- The main body of the car platform is made of high-quality structural steel, with strong bearing capacity, safety and durability.

- Equipped with balance valve, safety pressure, emergency stop and other safety devices.

- According to the user’s requirements, it can be realized under the stage, on the stage and by remote control.

The following car lift platform functions can be added according to user requirements:

- Infrared induction: the car does not stop to a suitable position, and the platform does not lift.

- Running warning light: flashing warning and intermittent alarm sound during platform lifting.

- Anti-drop device: After reaching the working floor, the anti-drop device is turned on. Lock the countertop.

- Remote control: The platform can be lifted and lowered remotely.

The scope of uses:

Widely used in 4S shops, large repair shops, multi-storey underground parking lots, home parking lots, etc. It is used to transport cars up and down between various working floors. 4s shop car lift, 4s shop car lift price runs smoothly and the work surface is large. Generally used for maintenance and other operations of large vehicles. During lifting, the noise is small, the power is large, the maintenance is simple and convenient, the maintenance cost is low, and the service life is long. 4s shop car lift, 4s shop car lift price is installed in the pit, when it descends to the lowest height, the work surface is level with the ground.

The car elevator manufacturers are professionally customized and customized according to the specific requirements of customers. Customers need to provide the following information:

| 1 | Lifting height and load capacity |

| 3 | The table size of the lifting platform |

| 4 | Lifting range |

| 5 | Operation mode, electrical control (electrical) configuration requirements |

| 6 | Installation environment (indoor or outdoor, it is inconvenient to transport and hoist) |

| 7 | Different configurations of various additional devices and structural forms |

When know the above information,our factory can provide a free design and price for your car lift.So,just contact us with the loading capacity,lifting height,platform size or car lift shaft size.We will send you the car lift solution asap.

The mobile dock ramp also called mobile dock leveler,loading dock ramp,hydraulic container loading dock ramp lift.

The mobile hydraulic dock ramp is a transition bridge used for forklifts to travel from the ground to the carriages when loading and unloading trucks. Its mobility can satisfy loading and unloading operations in different work sites. The load-bearing beam made of high manganese steel rectangular tube has high rigidity. The slope is made of toothed steel grating with anti-skid properties. The material of the fuselage has been shot blasted and rust removed, and a manual pump is used as the lifting power, which does not require an external power supply, which is convenient for outdoor use.

The mobile dock ramp is a mobile steel structure slope. The loading and unloading forklift can directly drive into the truck compartment for batch loading and unloading operations, which solves the problem that the forklift or manpower cannot directly load and unload due to the height difference between the truck compartment and the ground.

Features of mobile dock ramp:

- The power is divided into manual and electro-hydraulic, the voltage of the electric pump station is usually 220 (can be customized according to customer needs);

- The equipment load capacity is from 4 tons to 15 tons, and the height adjustment range is 0.80-1.70 meters

- The forklift loading ramp realizes safe and fast loading and unloading of goods, which doubles the efficiency of loading and unloading operations, and is suitable for trailers, semi-trailers, freight platforms and other logistics links;

- It is irreplaceable to provide convenience for various enterprises to load containers and terminal operations;

- Transfer to the working position at any time, which is simple, convenient, time-saving, labor-saving, and greatly saves logistics costs;

Structural advantages of hydraulic loading ramp

1.Height-adjustable support base to prevent the vehicle from tipping over. It is supported on the rear frame of the vehicle to prevent the forklift from overturning when the gravity is concentrated on the rear of the vehicle when the forklift enters the vehicle.

2.The slope surface of the dock ramp adopts high-strength toothed steel grating, which has anti-skid performance, so that the forklift has better climbing ability and maneuverability. Even in rainy and snowy weather, it can still guarantee normal operation.

3.The randomly configured brake pads can effectively prevent the dock ramp from slipping and moving when the forklift is walking on the container dock ramp.

4.The manual hydraulic pump is used as the power, and the height adjustment of the dock ramp can be easily realized without external power supply. At the same time, according to customer needs, optional DC power supply for lifting power.

5.The adjustable length chain is used to hook the vehicle, so that when the dock leveler is displaced by the truck, the dock ramp and the truck will not be disengaged.

So how to choose a sturdy and durable mobile container dock ramp?

First, William was telling us about his work scene and the specific requirements for the dock ramp.

Secondly, as a professional manufacturer of mobile dock ramp, our technical department has specially drawn drawings.

Finally, after all aspects were determined, William decided to purchase two adjustable loading dock ramps from our factory. In the production process, strict quality control is required, and after completion, multiple tests are required before delivery.

We’d like to share some delivery pictures for your reference:

If you also have needs or questions about dock ramp,welcome contact us at any time. We are happy to share and learn more projects with you all.

The stationary forklift container hydraulic dock leveler is an auxiliary equipment for loading and unloading together with the storage platform. Dock ramp is integrated with the platform. Container ramp can be adjusted up or down according to the different heights of the truck compartment, which is convenient for forklifts to drive into the compartment. The container ramp adopts imported hydraulic pump station.Except that,there are anti-rolling skirts on both sides.This kind of dock ramp is more safer and the work efficiency is also improved greatly.

This fixed dock ramp was exported to South American.Or order to help you know more about this lifting equipment,we’d like to share the dock ramp standard main specifications as follows:

Load capacity: 6 tons, 8 tons, 10 tons, 12 tons, 15 tons

Table size (mm) : 2000*2000 / 2500*2000

Lip size (mm) : 400.

Stroke(mm) : +400-300.

Motor power (kw) : 0.75.

Closed height (mm): 600

Pit size L*W*H (mm) : 2060*2060*610 / 2560*2060*610

If you want to know the dock ramp structure in details,kindly check the drawing for your reference.

Advantage of hydraulic forklift dock ramp

A. The electro-hydraulic height of dock leveler can be adjusted arbitrarily, which improves the loading and unloading efficiency of the hydraulic container dock ramp. It adopts full hydraulic drive, which is easy to operate and reliable in operation.

B. The lip plate and the platform are connected by a full-length shaft, which has high strength and good reliability.

C. Imported integral hydraulic station is adopted, which has good sealing performance and long service life

D. The high-strength U-beam design can ensure long-term operation under high load without deformation.

E. The non-slip template is adopted to make the platform have good anti-slip performance.

F. On both sides of the apron board, to prevent the toes from entering the platform and causing accidental injury.

G. Support personnel should be provided for maintenance of maintenance personnel.

H. High electro-hydraulic efficiency, easy operation, adjustable height, wide adjustment range, high loading and unloading efficiency, saving manpower. Make your work more convenient, labor-saving and cost-saving.

J. The platform lap plate is always attached to the carriage so that moving vehicles will be covered with flat ground.

K. In addition to the standard size rubber bumper pads, different sizes of bumper pads are also available for safe parking.

The main material of container dock ramp is steel plate. The quality of different steel plates determines its price. If the quality of the steel plate is better, it will take a long time to use.

As well, for the fixed dock leveler,or we can call it as platform forklift ramp, loading and unloading platform,there are many applications including:

Enterprises, warehousing, stations,wharf, warehousing & logistics base, postal transportation, logistics and other units cargo loading and unloading.

Hydraulic vertical cargo lift moves materials–in factories, warehouses, industrial plants, institutions—anywhere that products or supplies need to move from one level to another. provides fast, efficient,convenient and safe access to mezzanines, balconies, basements, and any levels in multistoried building. It can be installed indoor and outdoor applications.

In addition to the safety devices of freight elevator, hydraulic cargo elevators are also equipped with:

1.Overflow valve: to prevent the system pressure from being too high during upward movement

- Emergency manual valve: when the power supply fails, it can make the car emergency drop to a relatively low level. Open the door near the floor,

- Hand pump: when the system fails, the hand pump can be operated to pump out high-pressure oil to make the car rise to the nearest floor;

- Pipeline rupture valve: when the hydraulic system pipeline breaks, the car stalls and descends , it can automatically cut off the oil circuit to stop descending.

- Oil temperature protection of oil tank: When the oil temperature in the oil tank exceeds the standard set value, the oil temperature protection device will send a signal to suspend the use of the elevator. When the oil temperature drops, the elevator can be started.

- Low cost: generally, the cargo lift cost is much cheaper than scissor lift

- Low failure rate: Due to the use of advanced hydraulic system and good control methods, the failure rate of elevator operation can be reduced to a relatively low level.

- Low power consumption: When the hydraulic elevator goes down, it is driven by the pressure generated by its own weight, which greatly saves energy.

Civil engineering advantages of hydraulic cargo lift :

- There is no need for a machine room above the hoistway, and the top floor can be installed with a height of more than 3.5 meters.

- The machine room can be located within a radius of 15 meters of the well, occupying an area of only 3-4 square meters.

- The hydraulic cargo lift platform does not have a counterweight device to improve the utilization rate of the well area.

- The hydraulic cargo elevator load and load directly act on the foundation pit through the oil cylinder, and the hoistway strength requirements are low, and the brick structure or brick-concrete structure hoistway can be used.

The cargo lift is belong to custom made product, and we always produce it according to every client’s requirement. Before quotation, we need know the lifting height, load capacity and platform size you need. Then we could design a most suitable cargo lift platform for you.

What are the anti-shock safety measures during the production of hydraulic lift platforms?

Mobile lift platform is an important operating machinery and equipment in modern high-altitude operations.

Pay attention to safety in welding production of lifts. Today, take you to understand the safety measures of the lifting machine.

(1) The production staff of the lift platform must hold a certificate, and no witnesses must be welded and cut.

(2) The welding and cutting equipment of the lifting platform should have a good isolation and protection device, and have an independent electrical control box.

(3) The shell of the welding and cutting equipment and the shell of the electrical control box shall be equipped with a protective connection device.

(4) When replacing the welding and cutting equipment connection or replacing the welding part, replace the secondary circuit, transfer the workplace, and replace the fuse or welding cutting equipment. The power must be cut off.

(5) Welders must wear welders’ gloves when replacing electrodes or wires during the production process. Welders gloves should be dry and insulated and reliable. For welding operations for high -bellied voltage and welding voltage or wet environment, welders should use insulation rubber pads to ensure the insulation of the body and welding parts. Especially during the summer work, the clothes are wet after sweating, and the body does not allow contact with the welded parts and the workbench.

(6) When welding in a metal container or narrow workplace, a special protective device must be used. Such as the insulation rubber pads, insulation shoes, insulation gloves, etc., to ensure the insulation between the welded body and the charger.

(7) When working in a dark environment with insufficient light, handheld lighting must be used. Generally speaking, the lighting voltage should not exceed 36V. In humid, metal containers, and other dangerous environments, the lighting voltage should not exceed 12V.

(8) When welding and cutting lifts, we should not wear shoes or cloth shoes with nails. The insulating gloves should not be less than 300mm. The production materials should be soft leather or canvas.

When customers need a multi-floor freight elevator, they often need to customize some equipment, because it is very difficult to rely solely on manual handling, so customizing the freight elevator is also a prerequisite for transporting goods. How to customize the freight elevator? What should we know before customizing? The following elevator manufacturer-WIZ LIFT will give you some suggestions, hoping to be helpful to customers who customize hydraulic elevators!

What parameters do you need to know when customizing a freight elevator?

1. We need to understand the load capacity. When customizing the lift, there will be a rated load capacity. Customers can choose according to the load of their own cargo, such as 500kg/1000kg/2000kg and other specifications. The maximum load capacity of the lift can reach 30 tons.

2. The lifting height of the elevator, which also refers to the stroke of the equipment, is the distance from the plane that needs to be lifted to the middle of the platform where it stops. What some customers tend to confuse is how to calculate the height from the first floor to the second floor. This refers to the height from the ground of the first floor to the ground of the second floor.

3. The size of the cargo platform should also be carefully calculated. Generally, the size of the upper and lower elevators should be calculated. What needs to be reminded is that the platform of the elevator should be larger to facilitate the transportation of goods, and it cannot be used because it is too small. If the guide rail type elevator needs to be installed in the shaft, the size of the shaft needs to be considered when designing the lift table.

4. To consider the direction of entry and exit, the position of the door opening is very important, which directly affects the installation direction of the guide rail lift.

Regarding the parameters that you need to know about custom-made lifts, the freight lift manufacturer – WIZ LIFT will introduce you here, and I hope it will be helpful to you.

The cargo lift is more flexible and can adjust the platform. Customers who have used it should know that the goods lift is a customized product, and the size and installation site of the freight elevator platform can be designed according to its own site environment. Therefore, there will be a period of running-in period after the hydraulic pallet lift platform is installed.

The running-in of the small goods lift is also called the running-in. It is the initial trial stage of the rail-chain type elevator. It is the basic stage to ensure that the parts are fully contacted, rubbed, adapted, and shaped. The capacity, longevity, safety, and economics of the environment will have an important impact. Therefore, a reasonable running-in elevator is particularly important. At this stage, special attention should be paid to some problems that are prone to occur:

1. Due to the looseness of lifting platform parts, vibration and the influence of machine heat, leakage will occur at the sealing surface of the machine and pipe joints, hydraulic pump station, oil cylinder and oil pipe joints.

2. Although the cargo lift tablehas been run-in according to the regulations before leaving the factory, the surface of the parts is still rough. In addition, there are many metal particles falling off between the new parts, which intensifies the wear.

3. The fallen metal shavings enter the hydraulic system and cause blockage of the oil circuit, which may cause malfunctions such as stuck parts, heat generation and leakage.

4. Fasteners in the rotating parts of the lifting platform are easy to loose. Due to alternating loads such as vibration, impact, and overload during transportation and use, it is easy to loosen the originally fastened parts.

5. The operator of vertical warehouse forklift lift platformis not familiar with the equipment and the operating procedures, which may cause operational errors, easily cause failures, and even cause accidents. Therefore, the operator of the lift must study carefully and be familiar with it before taking up the job.

Safety operating procedures for cargo lifting platforms

The development of the hydraulic cargo lift is at a peak state. Since most manufacturers or individuals choose multi-storey buildings in order to improve the utilization rate of the site, a device is also needed to facilitate the lifting and lowering of cargo. Due to the high cost and low carrying capacity of ordinary elevators, it is not suitable for loading goods of tens of tons or hundreds of tons, so hydraulic lifts and hydraulic lifting platforms with high carrying capacity have been developed. Hydraulic lifts to assist production and cargo transportation.

Safety operating procedures for hydraulic freight elevator used for cargo lifting:

1. The use of the lifting platform must be operated by the company’s designated personnel (filed by the Ministry of Personnel and Security), and the work position must be strictly guarded; non-designated personnel are not allowed to use it without authorization.

2. Before using the lifting platform, first check whether the doors of each floor are closed, whether the emergency stop switch is reset, (reset the emergency stop switch, turn clockwise) and check the side of the emergency stop switch, complete

operation can then be started.

3. It is strictly forbidden to take people on the hydraulic lifting platform.

5. For example, the hydraulic goodsplatform has a load capacity of 3000kg and must not be overloaded.

6. When using the cargo lift tableto transport goods up and down, place the goods in the middle of the car as much as possible to avoid the goods being tilted and jammed during operation, and the platform must not be started when the goods are stacked unstable.

7. When abnormal conditions are found during the use of the platform, the operator should stop the operation of the platform and report to the equipment department to send personnel to repair it;

8. After the goods lift tableis used, the operator stops the platform on the ground floor, closes the landing door, turns off the key power switch, and turns off the main power supply.